The nest swing is called nest swing chair, or bird nest swing, it is a kind of round net swing, that can be hung to the ceiling, or to the swing frame, whatever steel or wooden frame, also can be fixed to the tree with extension rope or straps. And then we can swing on the mat, and this swing can hold more than 600lbs, so it can be suitable for age 3-103, it passed the GS testing, and also ASTM F1148, no concern ab the safe swing.

What is a nest swing?

What types of nest swing are there?

In the past few years, with the development and progress of the children’s outdoor toy industry, there have been great changes in the nest swing. As an outdoor toy manufacturer with 18 years of experience in the process of cooperation between us and our customers, the two sides combined with market feedback, continuous communication to develop and improve nest swing, including optimizing product shortcomings, increasing product features and improving product performance. The more than 100 nest swing currently on sale have evolved from many years ago. This section will categorize our nest swings based on size, shape, and structure.

- Shape

Generally speaking, the shape of the kids nest swing is less, divided into round nest swing, nest swing oval, square nest swing, hexagon nest swing, and other custom shapes. The most popular is the hexagon nest swing. Rectangular and oval also called platform swing, because of their shape, the swing seat play area are large, suitable for more than one child to play at the same time, but the cost of rectangular will also be higher. The hexagon swing is a new shape that we have just developed, and this hexagon swing has been loved by our partners since its launch.

- Size

Similar to the shape, the regular size of the kids nest swing is less, the best sell size is the dia. 40inch size, size selection:24, 30, 35inch for one kid play. multiple children play at least 40inch or choose other shapes nest swing. If you are a toy store operator, our purchasing advice is to purchase more 40inch sizes.

- Structure

According to the main structure of the kids nest swing, our swing can be divided into these categories: foam knot nest swing, detachable nest swing, hollow nest swing, foldable nest swing chair, nest hammock swing chair, and nest swing tent. The following pictures take you to clearly understand these types of products.

Foam Knot Nest Swing

Foam Nest Swing is a nest swing structure that swing steel tube wrapped by NBR-foam, PE Hanging rope through the steel tube hole and then hotting knot to make it fixed, the swing hanging rope is not removable. This structure has the adventures of easy assembly (fully assemble or swing steel tube disassembly), large capacity, durability, and only 3 steps to complete the installation, for children's entertainment

Hollow Nest Swing

Hollow nest swing is one of our patented designs, and it's different from traditional nest swing, kid can wear through his feet form the middle of the hollow swing seat for a more comfortable position to play. At the same time unnecessary to worry about safety, our swings will have a professional test to ensure the safety of users.

Nest Hammock Swing Chair

Nest hammock swing chair is a kind of kids nest swing, including foldable ourdoor nest swing chair, macrame nest swing chair, rectangular platform nest swing chair and so on. Nest swing chair can provide a more comfortable sitting position, indoor and outdoor can be used, and water resistance is very good.

Summary of this chapter

Sort by size:

24inch nest swing

30inch nest swing

35inch nest swing

40inch nest swing

60inch nest swing

Sort by shape:

round nest swing

nest swing oval

square nest swing

hexagon nest swing

Sort by Structure:

foam Nest Swing

hollow Nest Swing

nest swing chair

For nest swing business, please contact us!

How to make nest swing?

Introduction

Maybe you don’t know much about the production process of nest swing, or you are interested in learning more about the secrets of kid nest swing production. In this chapter, we will explain to you the production process of the nest swing and let you know some details about the production process. By reading this chapter, you will become an expert in the knowledge of nest swing!

The following will show you the entire process in production order

Nest swing produce process

1.Nest swing material

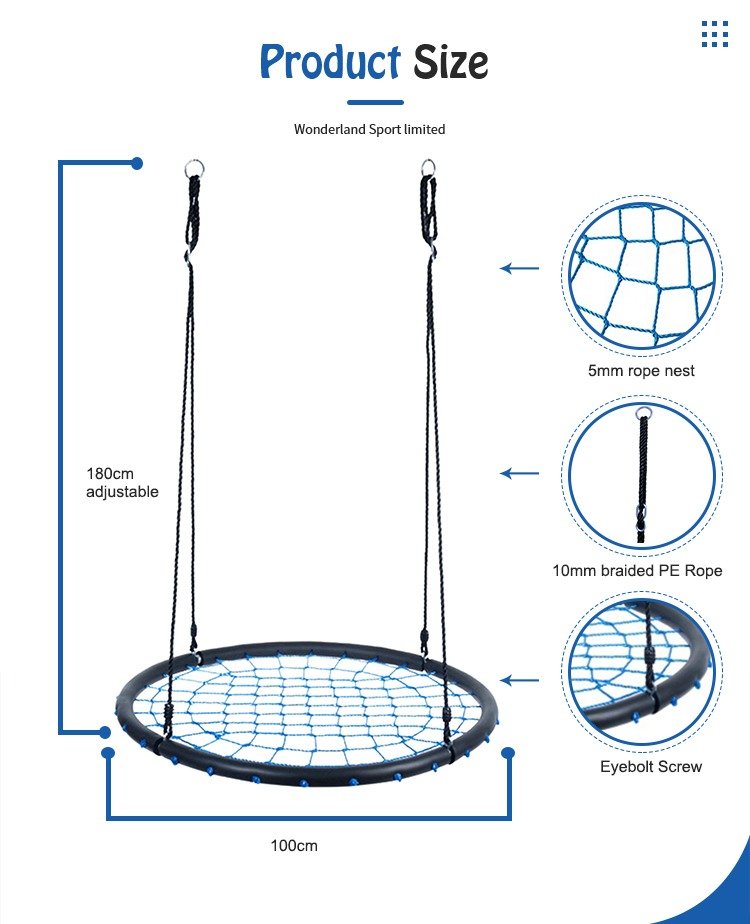

Before understanding the raw materials, we need to know the structure of the nest swing, the following picture shows you the name of each part.

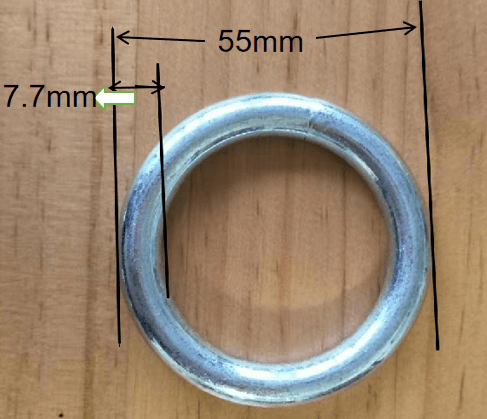

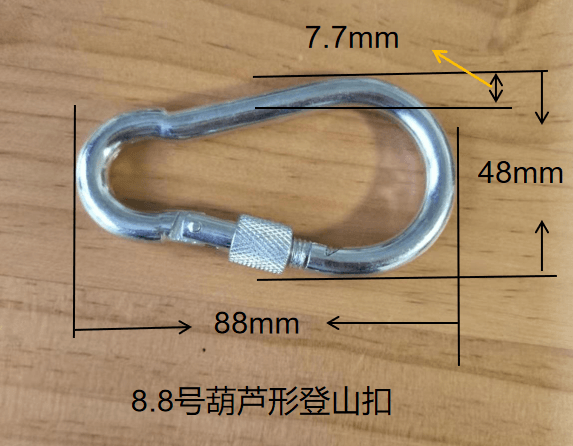

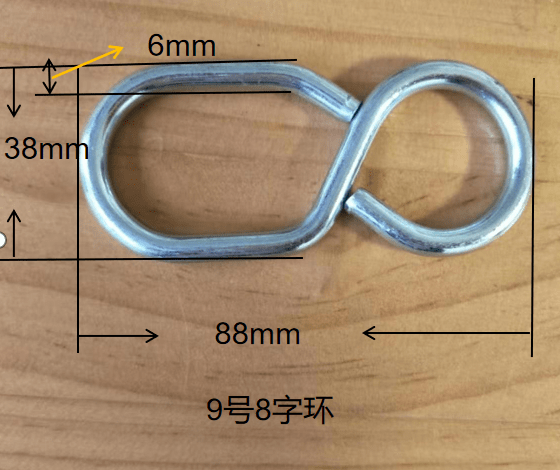

Splay ring

O-Ring

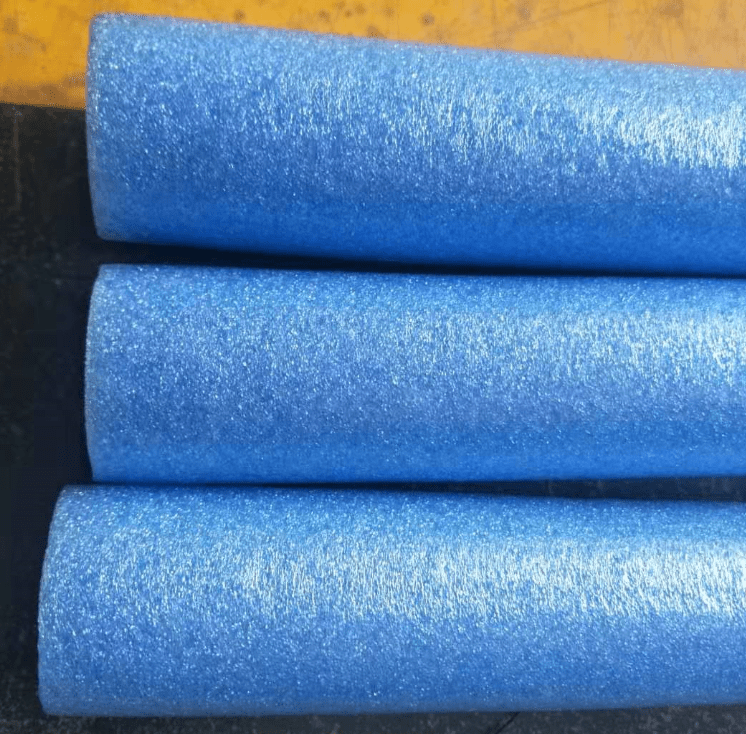

NBR Foam

PE Rope

PE Rope

Kids Nest swing generally has the following accessories: Steel pipe, Rubber foam tube(NBR Foam), EPE foam steel tube, PE net rope, PE hanging rope, PE winding rope, O-ring, Splay ring, Carabiners

2.Pipe cutting

Pipe cutting is the first step in the production of the nest swing, we will purchase back the steel pipe (according to customer demand, choose galvanized steel pipe or black skin pipe, etc.) according to the order quantity and size of the swing to determine the cutting the raw material steel tube.

3.Pipe contracting

Pipe Contracting refers to the combination of multiple steel tubes together, squeezing one side of the tube a little flatter, as shown in the picture.

4.Elbow

As the name implies, the two ends of the pipe are bent to fit together. The round nest swing will bend the steel tube into an arc, and the rectangular nest swing will bend the steel tube into a concave polygon.

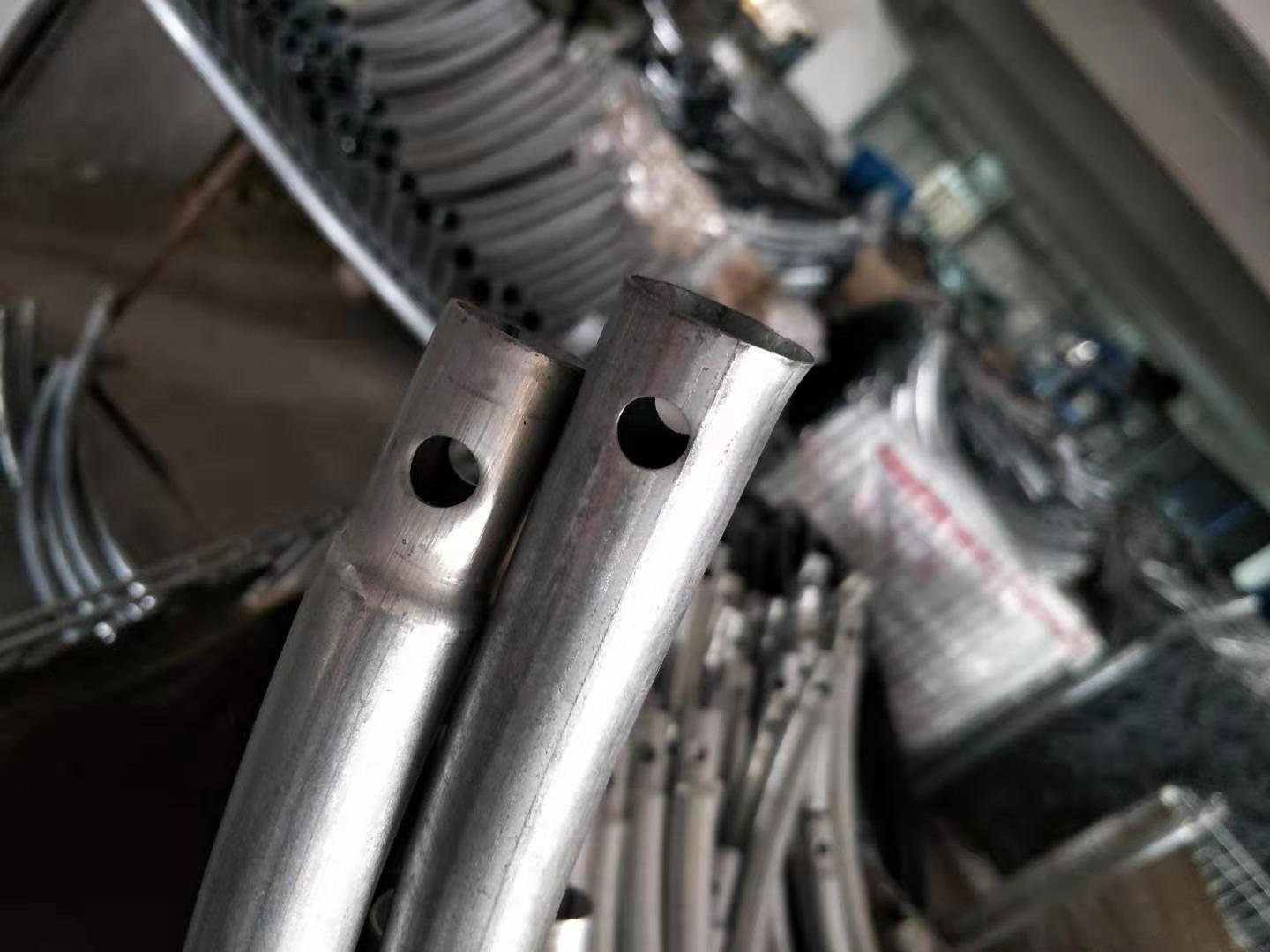

5.Punching

Make mounting holes for the link of two steel pipes

6.Drilling

Some nest swings do not require screw links, and the hanging rope is passed directly through the body of the product. Therefore holes need to be drilled to handle this.

7.Embedded cut-proof tube

This is a typical case of our nest swing process improvement. To prevent the PE hanging rope from being cut by the edge of the punch mentioned above during the use of the swing, causing safety problems. We added this design to the 25mm diameter steel pipe. Embedded in a cut-proof tube increases the durability of the swing.

8.Spraying

A steel pipe surface treatment process can improve the steel pipe surface’s beauty, and make it more corrosion-resistant. Before spraying, the surface of the steel pipe needs to be treated, such by removing oil, dust, and rust on the surface of the steel pipe

9.Injection Molding

The method of making the swing buckle, as shown in the video, the end of swing hanging accessories to be fixed by using this buckle.

Injection molding process is also used to produce plastic swing seat and other products

Related Reading:

- Professional analysis of Injection molding process

- The Ultimate Guide to plastic swing seat

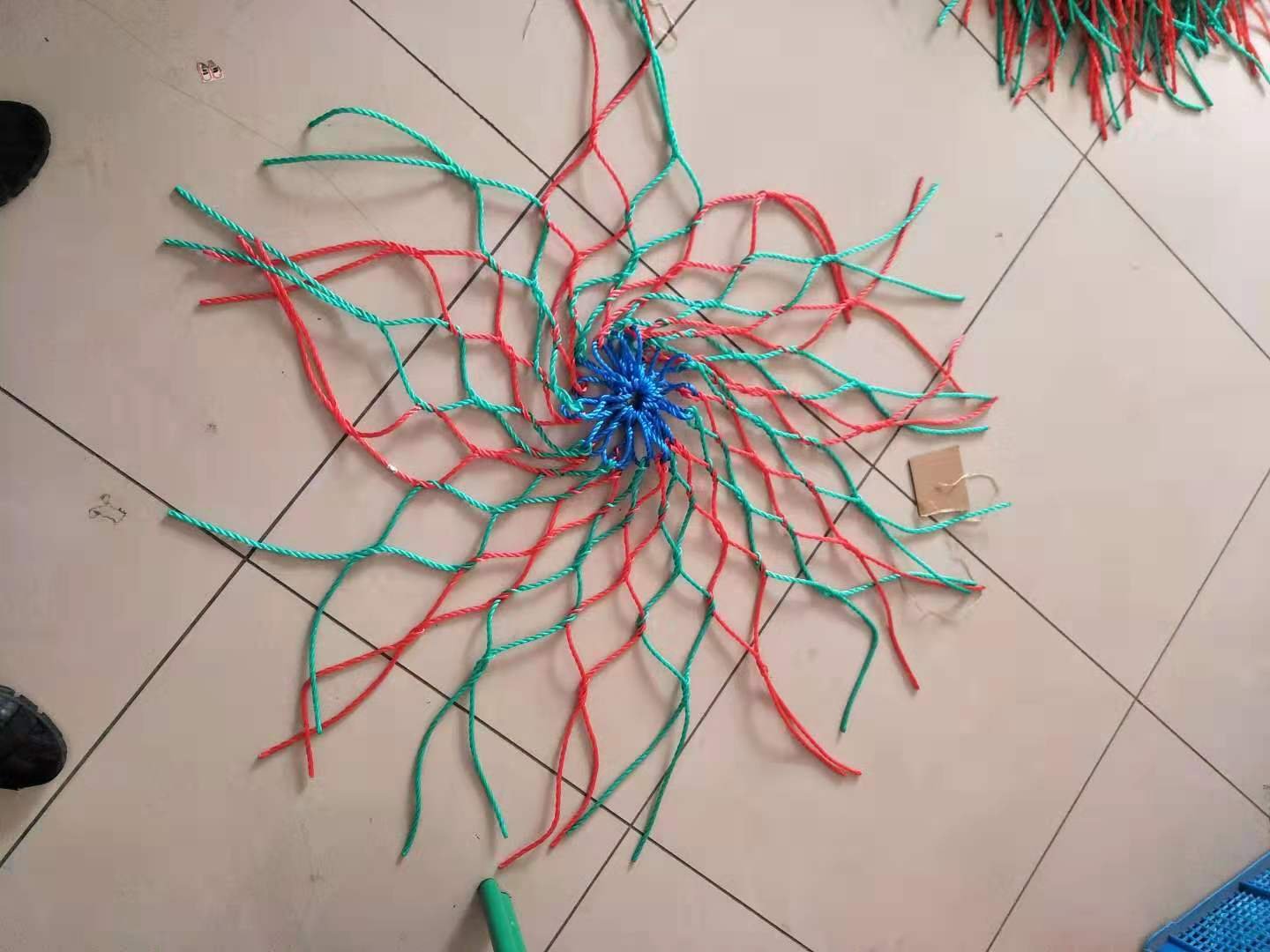

10.Weave nest

Weaving net refers to the production of the nest swing seat parts, before production will be based on the size and structure of the nest swing production structure chart, we have experienced workers according to the structure chart attached to the size and rope length to prepare the woven net. In the video, you can clearly see the netting process

11.Rope assemble

Assembling rope is to assemble the woven nest completed in the previous step into the swing steel tube frame, and adjust the structure of the woven nest, elasticity, pattern design, etc. according to our product production requirements.

12.Hotting knot

After the successful installation of the woven nest, in order to fix the rope through the steel tube frame of the swing, we use the hot knot technique, like the video shows: fixed pe net rope.

13.Packing

After product QC and assembly, we package according to customer’s customized requirements. The following two videos show single product packaging and customer’s requested palletized shipping method