Table of Contents

Introduction

Maybe you have seen the word saucer swing when shopping or you have seen pictures of this product

40inch saucer swing

Flying saucer tree swing

Heavy-duty 60inch saucer swing

at this time you may have these questions:

- Why is it called a saucer swing?

- How do you use a saucer swing?

- How do you make a saucer swing?

- Are saucer swings safe?

This blog will answer these common questions based on What is a saucer swing?

Why named saucer swing?

Saucer swing products first appeared around 2009, because of their shape like a saucer, the so-called saucer swing.

The initial saucer swing types and functions compared to the current saucer swing a big gap. Functionally consistent with the traditional swing, for children to play outdoors. Because the initial hanging way is not much more than hanging in the tree so is also called a saucer tree swing.

Development of saucer swing

After the launch of the saucer swing, because it has more than the traditional swing with a larger load, more expandability, and other advantages, received a lot of consumer love, more and more people began to know saucer swing and try to buy saucer swing.

Quality development

The initial saucer swing in raw materials and technology level is not high, especially since the product manufacturer does not have safety standards. Make its safety performance is not too stable, the child in the harvest saucer swing brings joy at the same time, facing the safety risks. This situation began to improve in 2010, Wonderland Sport this year into the outdoor sports game industry. According to the previous experience accumulated in the outdoor sports industry, the production of saucer swing was improved. Including raw material improvement, production quality control, product certification, and customer feedback.

Raw materials development

Saucer Swing Main Structure

Seat Mat

Steel tube

Hanging rope

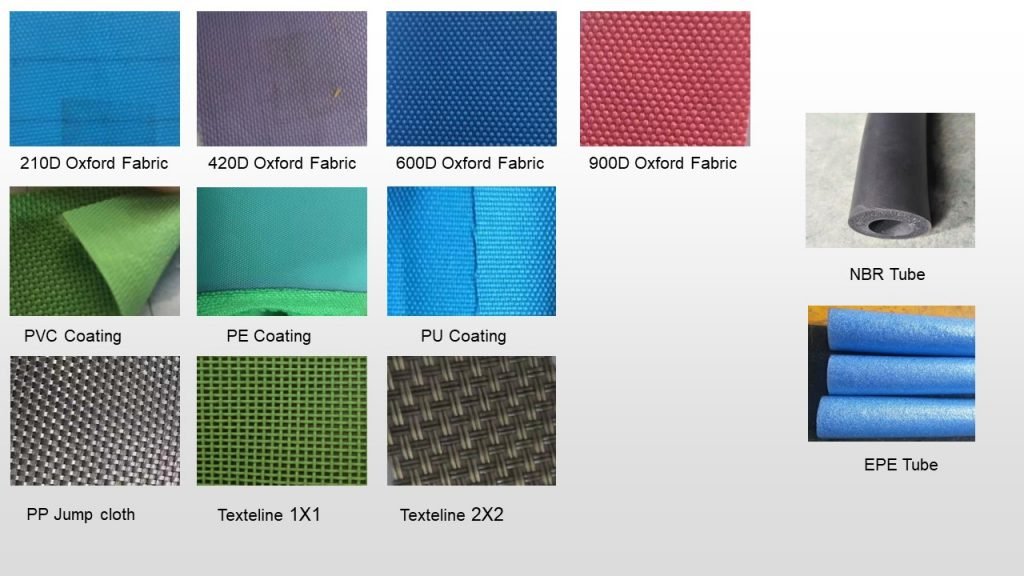

Swing Part: Galvanized pipe, PE mesh rope, Oxford cloth, pp mat with Texteline. Please check the list of raw materials comparison and features.

Saucer Swing Part |

Wonderland Sport |

Other Suppliers in 2010 |

Features |

|---|---|---|---|

|

Steel Tube |

Galvanized pipe |

Black/ white -skinned pipe |

Solid, Rust protection |

|

Rope Suspension |

φ10.5mm |

φ8mm |

More Durable |

|

Oxford fabric |

600D/900D |

420D |

More Waterproof, Durable |

|

Material |

Oxford, PP Mat (Patented style), Texteline |

Oxford |

More durable and environmentally friendly |

Production quality control development

In order to ensure product quality, wonderland sport gradually improves the in-production quality control system (IPQC), such as

1. IQC(Incoming Quality Control)

Steel:

- Steel dimensions must be in accordance with drawings or company contract requirements.

- Allowable tolerance of steel thick wall: -5%, allowable tolerance of steel pipe outer diameter: -2%

- Steel is straight and free from defects such as damage, cracks, rust, strains, thin oxide, and burrs on the surface

- Steel with bending requirements needs to be 60 ° bending test, does not allow cracking or creasing.

- Steel fit: steel with fit requirements, required to fit test fitting.

Aluminum:

- Aluminum outline dimensions must comply with the drawings or company contract requirements”

- Allowable deviation of aluminum thick wall: -5%.

- Aluminum tube outside diameter allowable tolerance: -2%

- No cracks, bruises, dents, bubbles, impurities on the surface of the tubing, clean and dry surface of the tubing, no oil and other debris allowed; uniform oxidation effect of aluminum tubing.

- Aluminum with bending requirements needs to be 60 ° bending test, does not allow cracking or creasing.

- Aluminum fit: aluminum with fit requirements, required to fit the trial installation.

- Material according to the company contract requirements: such as iron, aluminum, stainless steel, etc., surface treatment according to the company contract requirements.

- The surface of the plating is uniform and bright, without flaking, bottom exposure, spots, color difference, pockmarks, rust, and other defects.

- Screws, gaskets, rivets, wrenches, and round nails cut smooth, straight, round, and smooth, with o burrsScrew grain is clear, with no gnawing phenomenon.

- When using the actual screwdriver, the head of the screw cannot have serious wear and cannot affect the re-use.

- When the actual use of a wrench, the wrench can not have obvious wear and tear, not affect the re-use”

- Screws, gaskets, rivets, wrenches, ground nails without mutilation”

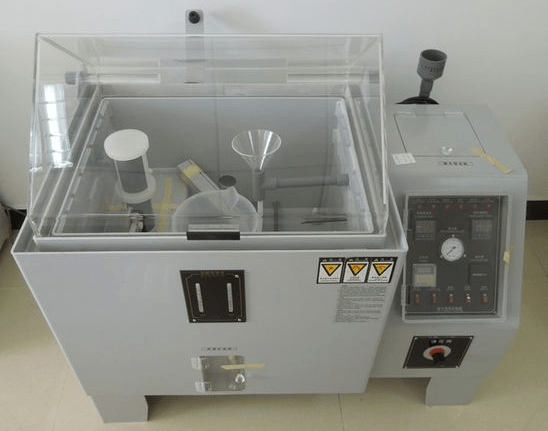

- The anti-corrosion performance of metal parts (salt spray test) shall conform to ISO9227 standard. ( 5% salt spray 24H, no rusting)

- The material meets the company contract requirements

- PE rope without color difference, to have contrast with the contract requirements color card

- The surface is not allowed to have a silk thread head, broken, hot knot cannot have a burr.

- Size in line with the company contract requirements, diameter or width tolerance: ± 0.5mm

- Tensile strength > N, can not be an instantaneous burst of force.

2. IPQC(In Put Process Quality Control)

Shaping

- “Confirmation of marking sample (first piece confirmation), The specimen should be signed by the workshop supervisor and the quality control officer together, and the operating personnel must be clear about the requirements of the specimen and mold it according to the specimen”,

- “Check the raw materials, do not allow defective products into the process” Material, specifications, size, wall thickness requirements in line with the company contract requirements”Cutting pipe mouth inside and outside does not allow a batch of sharp, pipe mouth flat and pipe surface into 90°”

- Bending curvature requirements can be normal and accurate into the calibration die, the pipe to maintain a smooth round, the pipe surface does not allow obvious wrinkles, pits, crushing, pinching, cracks, twisting, deformation, and other defects”

- Shrink tube The shrinkage tube does not allow cracks, pinching, and other defects”

- Drilling and punching Drilling and punching holes should be able to be put into the calibration die normally and accurately, and defects such as drilling deviation, punching distortion, punching breakage, dent marks, phi, and so on are not allowed.”

- Cutting bevels angles between parts and components match and defects such as cutting twist, misalignment, and batch front at both ends are not allowed, and they should be able to be put into the calibration die normally and accurately.”

- FlatteningBoth ends of the tube should be flattened evenly, without cracking defects”

- Product protection supervised the workshop to do a good job of product protection, in the handling, loading, and unloading, processing process gently, reasonable stacking neatly, do not allow defects such as bumps, bruises, knocks, bumps dents, scratches, etc., to reduce the lack of protection caused by the defective products into the next process”

- InspectionAccording to the requirements of the standard sample, the quality control personnel will conduct a sampling inspection according to the AQL sampling plan”

Welding

- Confirmation of specimen (first piece confirmation)The specimen should be signed by the workshop supervisor and the quality control personnel together, and the workforce must be clear about the specimen requirements and weld according to the specimen”

- Check the material of the previous process, do not allow bad products into this process” spot welding 1) in accordance with the standard sample or drawings, do not allow the wrong welding materials, put the reverse parts2)Require the parts to be put into the welding mold normally and accurately (easily), each welding point must be spotted twice or according to the product structure, the parts must be placed flat, no misalignment, knocking injury, knocking concave fittings(3) welding die positioning points must be pins, and the nut can not be skewed, to ensure that the assembly hole distance, the hole without welding slag, burrs, and other defects

- Add welding(1) fish-scale welding requires fish scale pieces of uniform size, smooth, 4 to 5 pieces per centimeter is appropriate, requires no burr, no grinding(2) the weld joint can not be too large or too small, the width of the weld seam control in 5 ~ 6 mm is appropriate(3) welded joints welded full, the interface is flat, the closure should be on the side, welded joints higher than the surface of the tube 3 ~ 4mm is appropriate(4) The seat and stress point of aluminum full woven rattan products require full welding, other tubes plus welding two-thirds(5) welding requirements firmly, no leakage, false welding, misalignment, porosity, gaps, electric flowers, and other defects”

- Product protection supervised the workshop to do a good job of product protection, in handling, loading, and unloading, processing process lightly, reasonable stacking neatly, do not allow defects such as bruises, bumps, knocks, dents, scratches, etc., to reduce the lack of protection caused by defective products into the next process “

- InspectionAccording to the requirements of the standard sample, the quality control personnel will conduct a sampling inspection according to the AQL sampling plan”

Grinding

- Confirmation of specimen (first piece confirmation)The specimen should be signed by the workshop supervisor and quality control personnel together, and the operator must be clear about the specimen requirements and grind according to the specimen”

- Grinding(1) first check the material of the previous process, do not allow bad products into this process2)Pipe interface is flat, with no deformation, gap, batch front, and other defects3)

- The welding seam must be smooth and integrated after grinding, with no cracks, pits, perforations, misalignment, grinding marks, and other defects(4) clear lines of cast aluminum parts, can not have a die-casting flying edge, sharp edges, gaps, cracks, trachoma holes, and other defects5)

- After grinding, there should be no coarse sand marks on the welded joints, no obvious tube injuries, and no stripes and wrinkles in the hand to avoid affecting the subsequent painting effect. (6)

- Woven rattan products require smoothness after grinding, no welding wire head, welding slag, burr, scratching hand and other defects”

- Appearance1)Surface A is flat and smooth, no defects such as wounded pipe, pinhole, dent, mark, scratch, and polishing trace are allowed(2) B surface polished smooth, no burrs, welding slag, weld wire head, and other defects”

- Product protection Supervise the workshop to do a good job of product protection, in handling, loading, and unloading, processing process gently, reasonable stacking neatly, do not allow defects such as bumps, bruises, knocks, dents, scratches, etc., to reduce the lack of protection caused by the defective products into the next process”

- Inspection According to the requirements of the standard sample, the production staff will conduct a full inspection, and the quality control staff will conduct a sampling inspection according to the AQL sampling plan”

Painting

- Confirmation of sample (first piece confirmation)The specimen should be signed by the workshop supervisor and the quality control personnel together, and the operating personnel must be clear about the specimen requirements and paint according to the specimen”

- Pre-treatment. (1) iron products after pretreatment phosphate film uniform, no oil, rust spots, yellowing, hanging ash, water stains, and other phenomena. (2) aluminum products after pretreatment without oil, blue, hanging ash, residue, water stains, and other phenomena.(3) all parts of the tube surface oxide film treatment clean, to avoid affecting the adhesion of the coating”

- On-line: 1) comprehensive inspection of the upper channel materials, does not allow the inflow of defective products.2) The surface of the workpiece is smooth and flat, without defects such as oil, rust spots, yellowing, hanging ash, water stains, bluing, and residue”

- Color: in line with the company’s contractual requirements of the color card number or color sample requirements, the entire product components without color differences, the same order without obvious color differences” adhesion and film thickness: 100-gram test, 2-grade pass, multi-point test.

- Film thickness uniformity generally requires more than 50um”

- Appearance.(1) the surface is smooth and clean, with uniform color, no leakage of spray, bottom, hanging, blistering, and other phenomena.2) A surface can not have chalk, miscellaneous points, or scratches. (3) welding dead ends can not have rust, and the inner wall of the pipe mouth can not have rust. “There are threaded holes that must be tapped after spraying”

- Product protection supervised the workshop to do a good job of product protection, in the handling, loading, and unloading, processing process, lightly hold, reasonably stacked neatly, do not allow defects such as bumps, bruises, knocks, bumps dents, scratches, etc., to reduce the lack of protection caused by defective products into the next process”

- Inspection According to the requirements of the standard sample, the production staff will conduct a full inspection, and the quality control staff will conduct a sampling inspection according to the AQL sampling plan”

Weaving the net

- Confirmation of sample (first piece confirmation)The standard sample should be signed by the workshop supervisor and the quality control personnel together, and the operating personnel must be clear about the standard sample requirements and compile the vine according to the standard sample”

- Material Check the material of the previous process first, and do not allow any defective products to flow into this process.”

- The weaving method is unified(1) in accordance with the standard sample, with even spacing, and no misplaced omission.2)The specification of braided net rope should meet the contract requirements. The surface of the net rope can not appear joints, broken wire, and other phenomena.”Hot knot1)According to the standard sample, the end of the rope should be firm, and the hot knot should not have burrs, burrs, or sharp points.2)

- Hot knot requires uniform size.”Rope winding1)Wrap the rope closely, the transition is natural, no wrinkle, crowded pile2) Winding rope surface does not accept joints, broken wire”Screw hole position can not be covered by braided mesh, rope winding”

- Product protection supervised the workshop to do a good job of product protection, in handling, loading, and unloading, processing process lightly, reasonable stacking neatly, do not allow bruising, banging, knocking, bumping dent, scratching, dust accumulation, etc., reduce the bad products caused by insufficient protection into the next process”

- Inspection According to the requirements of the standard sample, the production staff will conduct a full inspection, and the quality control staff will conduct a sampling inspection according to the AQL sampling plan”

Sewing

- Confirmation of sample (first piece confirmation)The sample should be signed by the workshop supervisor and the quality control personnel together, and the workers must be clear about the sample requirements and sew according to the sample”

- 1. The fabric grammage is allowed ±5g, with no color difference. If there are fireproof requirements, we should do the burning test, and if there are waterproof requirements, we should do the waterproof test.2, fabric label, hang card, tracking table, etc. should be correct”The direction of cutting is correct.

- The direction of cutting is straight, no raw edge is exposed, and there is no scratch line on the surface of the cloth. The stitch length ensures that there are 7 stitches per inch.”

- 1. Straight stitching, no wrinkles, no skipped stitches, no broken stitches, clean trimming of threads2. Sewing start and finish must be repeated with reverse stitch to ensure strength.”Product protection supervised the workshop to do a good job of

- product protection, lightly hold and place during handling and processing, reasonably stack neatly, do not allow touching dirty, dust accumulation, etc., to reduce the bad products caused by insufficient protection into the next process”

- Inspection According to the standard sample requirements, the quality control personnel will conduct sampling inspection according to the AQL sampling plan.”

Assembling

- Confirmation of specimen (first piece confirmation)The specimen should be signed by the workshop supervisor and the quality control personnel together, and the operating personnel must be clear about the specimen requirements and assemble according to the specimen”

- Uniformity of compilation method1)According to the standard sample, the spacing is even, with no misplaced omission.2)The specification of netting rope should meet the contract requirements. The surface of the net rope can not appear joints, broken wire, and other phenomena.”

- Rope winding1)Winding rope is tight, natural transition, no wrinkling, crowded pile2)Winding rope surface does not accept joints, broken wire”

- LanyardStrictly in accordance with the sample and contract requirements, can not appear pressure buckle or hot knot out of a number of broken wire and sharp points. Can’t have wrong wearing and leakage wearing phenomenon”

- Hot knot1)According to the standard sample, the end of the rope should be firm, and the ironing knot should not have burrs, burrs, or sharp points.2)The ironing knot requires uniform size.”

- Plastic partsNo color difference, deformation, cracking, burr, and pipe mouth fit should be good, pipe plug pull out the tension to be greater than 60NPlastic parts color to contract requirements color match”

- Metal hardware Fastened, no rust and corrosion, no omissions”

- Size Meet the company contract requirements, tolerance range: -3MM (appearance size)”

- Smoothness After flattening the bottom plane contact point error requirement in <2mm, error too large by the designated personnel for correction”

- appearance no bruises, burrs, batch fronts, pinholes, scratches, paint loss, dirt, rust, bad spraying, and other defects”

- Safety No gaps of 3 to 12mm, no sharp edges of sharp points, no shear extrusion points of 3 to 18mm”

- Strength test. According to the requirements of the contract or packaging instructions, can pass the maximum load.”

- Product protection supervised the workshop to do a good job of product protection, in handling, loading, and unloading, production process gently, reasonable stacking neatly, do not allow bruises, bumps, knocks, dents, scratches, dust accumulation, etc., to reduce the lack of protection caused by defective products into the next process”

- Inspection According to the requirements of the standard sample, quality control personnel according to the AQL sampling program for sampling inspection”

Riveting

- Confirmation of specimen (first piece confirmation)The specimen should be signed by the workshop supervisor and quality control personnel together, and the operator must be clear about the specimen requirements and rivet according to the specimen”

- First, check the material of the previous process, do not allow bad products into this process

- Riveting appearance requirements: no blooming, sharp edges exposed, rivet core residue and other phenomena, rivets or rivet buckles to maintain the rules do not deform.

- The strength after riveting meets the product’s functional use and testing requirements.”

- Product protection supervised the workshop to do a good job of product protection, in the handling, loading, and unloading, production process, lightly hold and place, reasonable stacking neatly, do not allow bruising, banging, knocking, bumping dents, scratches, dust accumulation, etc., to reduce the lack of protection caused by bad products into the next process”

- InspectionAccording to the requirements of the standard sample, quality control personnel according to the AQL sampling program for sampling inspection”

Packaging

- Confirmation of specimen (first piece confirmation)The specimen should be signed by the workshop supervisor and the quality control personnel together, and the workforce must be clear about the specimen requirements and pack according to the specimen”

- First, check the material of the previous process, do not allow the inflow of defective products into this process

- Stacked products require accurate quantity and firm bundling.

- Hanging card, barcode, color sticker: require an accurate pattern and text content, able to be scanned, and the position of pattern and text meet the requirements.

- Carton: size and material conform to the company’s contract requirements, no damage

- The name, quantity, specification, and illustration of spare parts in the instruction manual are complete and correct.

- Trial assembly. To strictly follow the steps of the instructions.”

- Product protection Supervise the workshop to do a good job of product protection, in the handling, loading, and unloading, production process, gently take and place, reasonable stacking neatly, do not allow bruising, banging, knocking, bumping dents, scratches, dust accumulation, etc., to reduce the lack of protection caused by bad products packed into boxes””

- Inspection According to the requirements of the standard sample, production staff full inspection, quality control staff according to the AQL sampling program for sampling”

3. Testing and certification

Wonderland sport’s saucer swing is the first batch to pass ASTM, EN71, and GS certification and is sold worldwide.

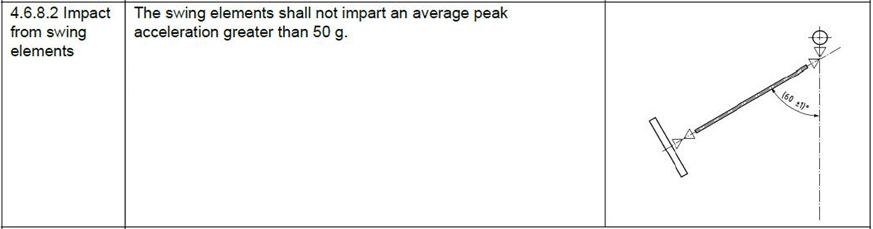

Salt spray test, package test, static load test, impact test, etc.

Package Test-Drop box

4. Customer feedback

In the process of cooperation with large customers, such as Intersport, customer feedback is collected through retailers and product improvement for problem points that arise.

The development of the saucer swing can not be separated from the continuous improvement and product development of the sellers and manufacturers. Category development: With the changing needs of consumers, heavy-duty saucer swings for many people, large size 60-inch saucer swings. and accessories like swing frames.

1 Comment